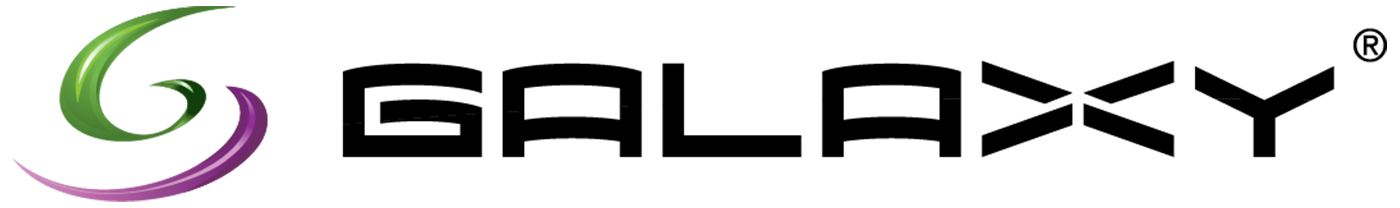

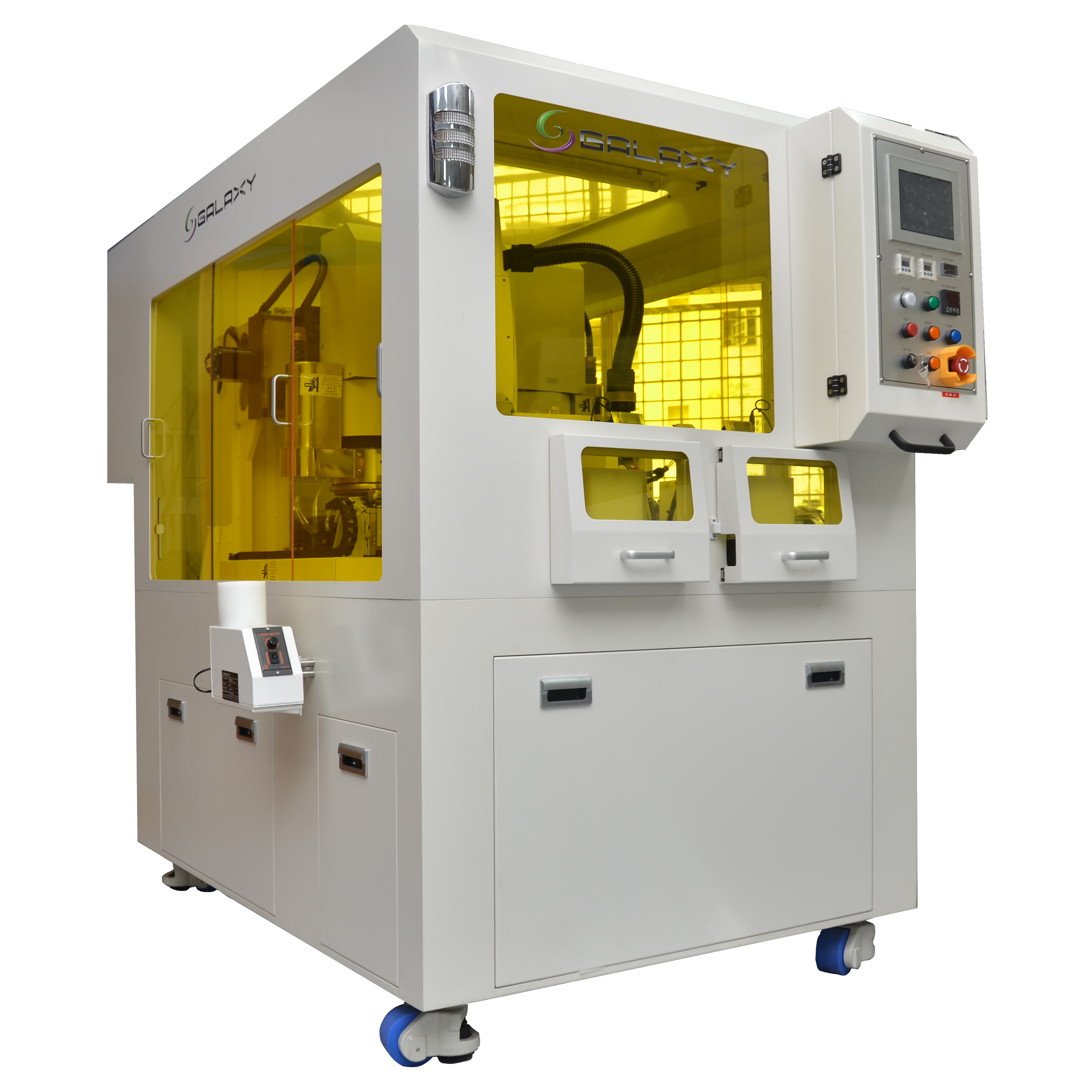

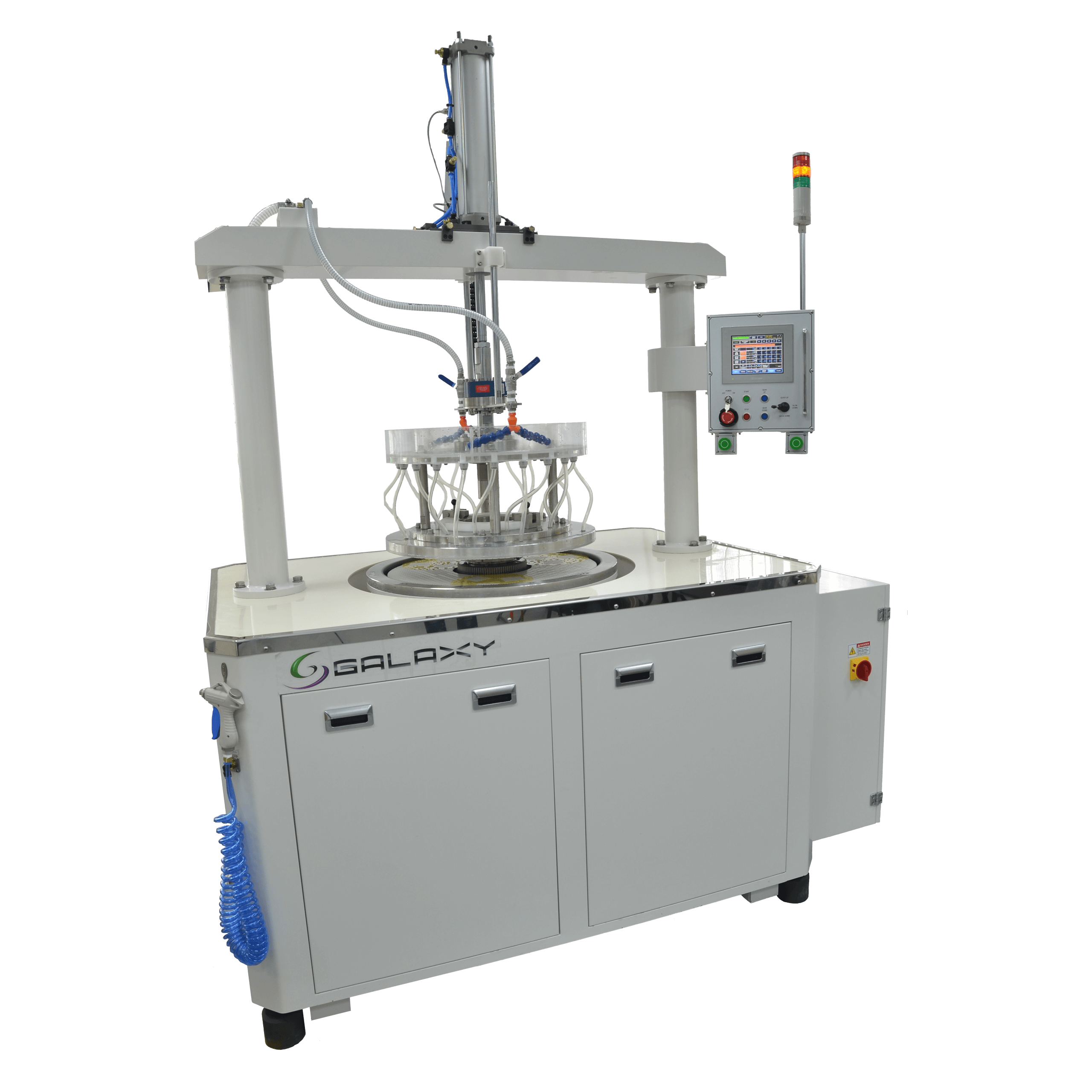

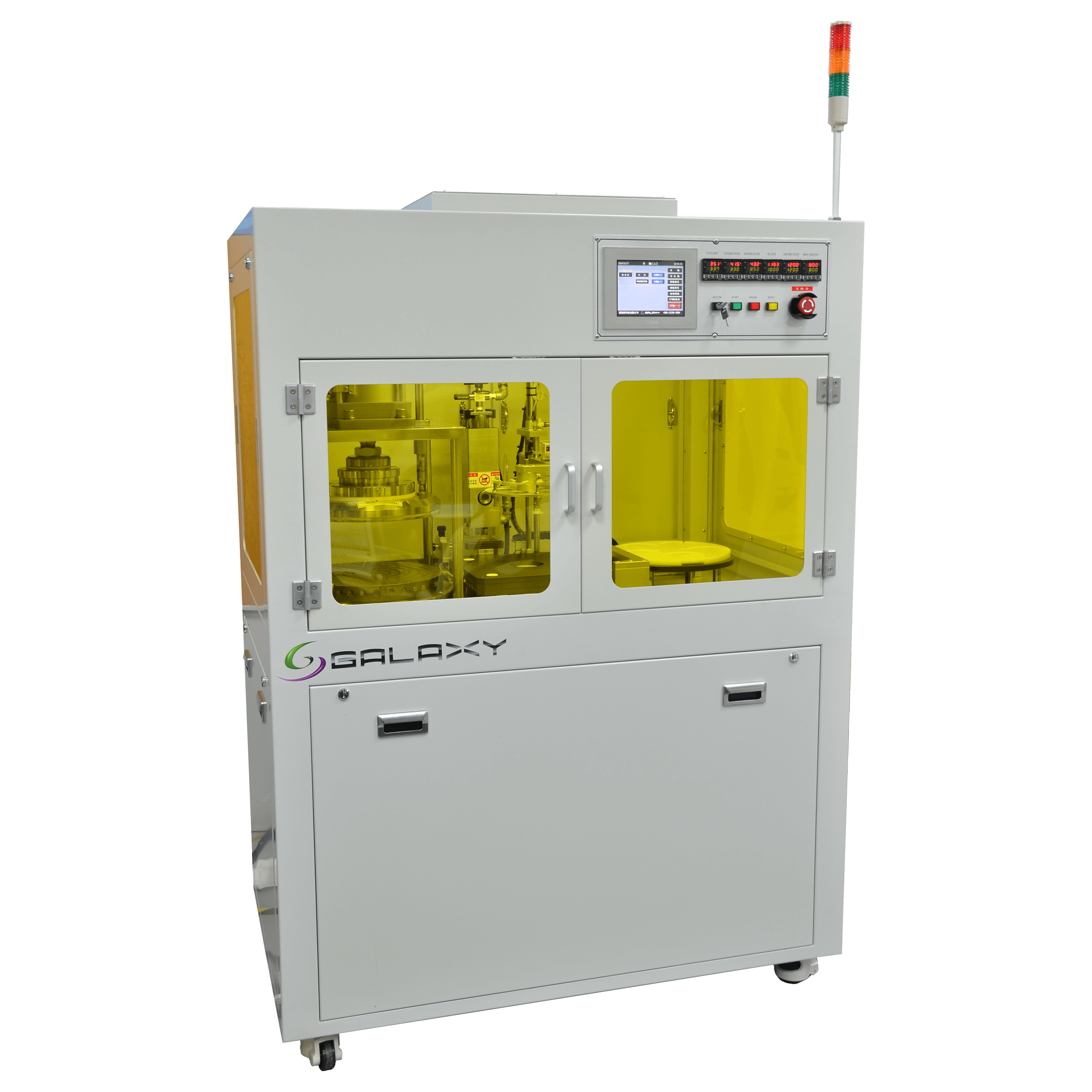

- Sort:Laser

GLS-200G

The cost-reducing wafer dicing and thinning technology achieves significant efficiency by fully automating the transfer between each process: laser processing, wafer separation, rough and fine grinding after crystal separation. Processing time is greatly reduced, eliminating the need for the lapping process, resulting in a 50% increase in yield.