- Sort:Mavlipa

G3

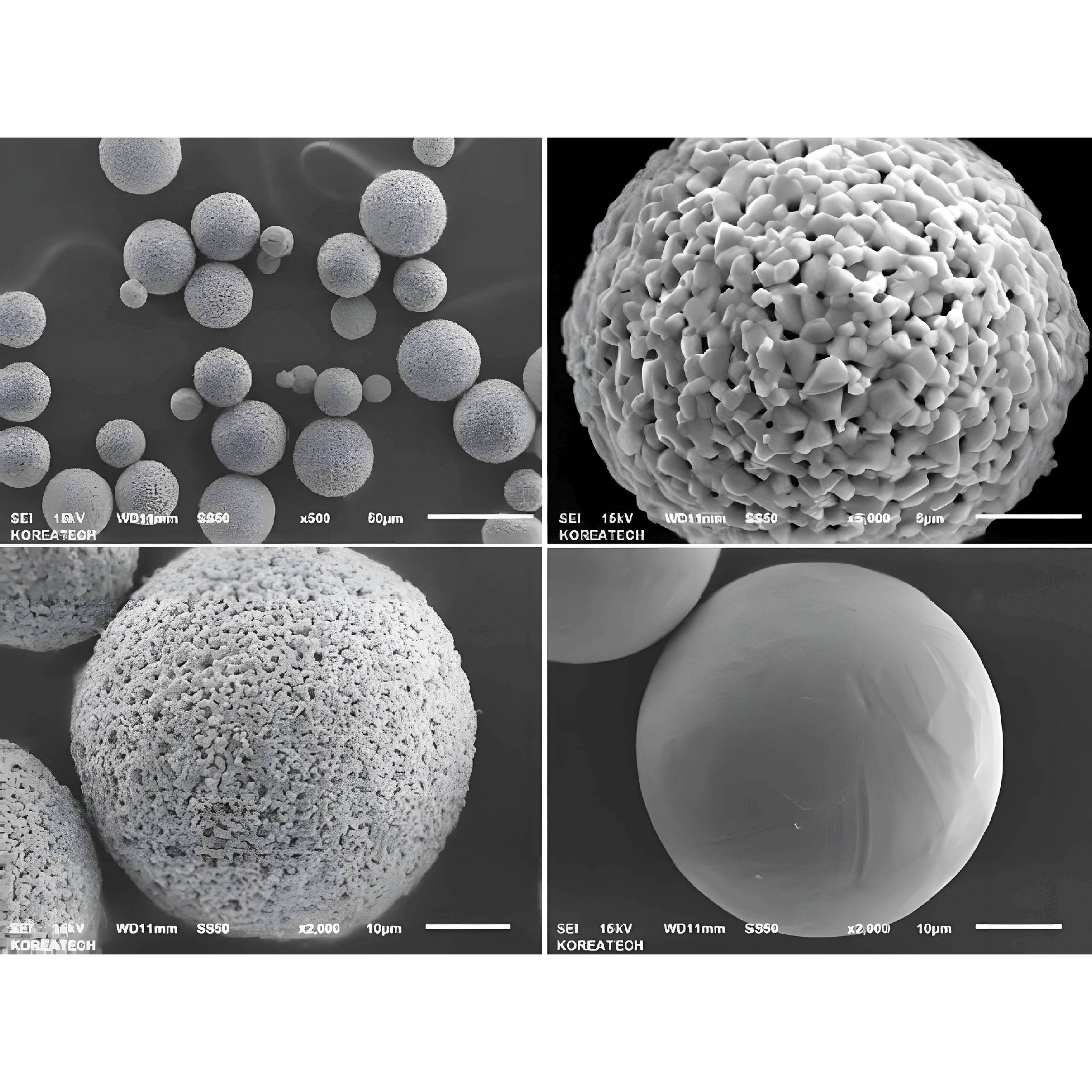

The Mavlipa G3 is a "3rd Generation" solution specifically designed to address slurry metrology challenges in semiconductor Chemical Mechanical Planarization (CMP). It is currently the only instrument on the market capable of providing real-time, undiluted measurements of Particle Size Distribution (PSD) and Large Particle Count (LPC) for all types of slurries, including high-concentration opaque solutions like Ceria or Silica. Its compact design and patented optical technology make it a critical monitoring tool for maintaining semiconductor device yield