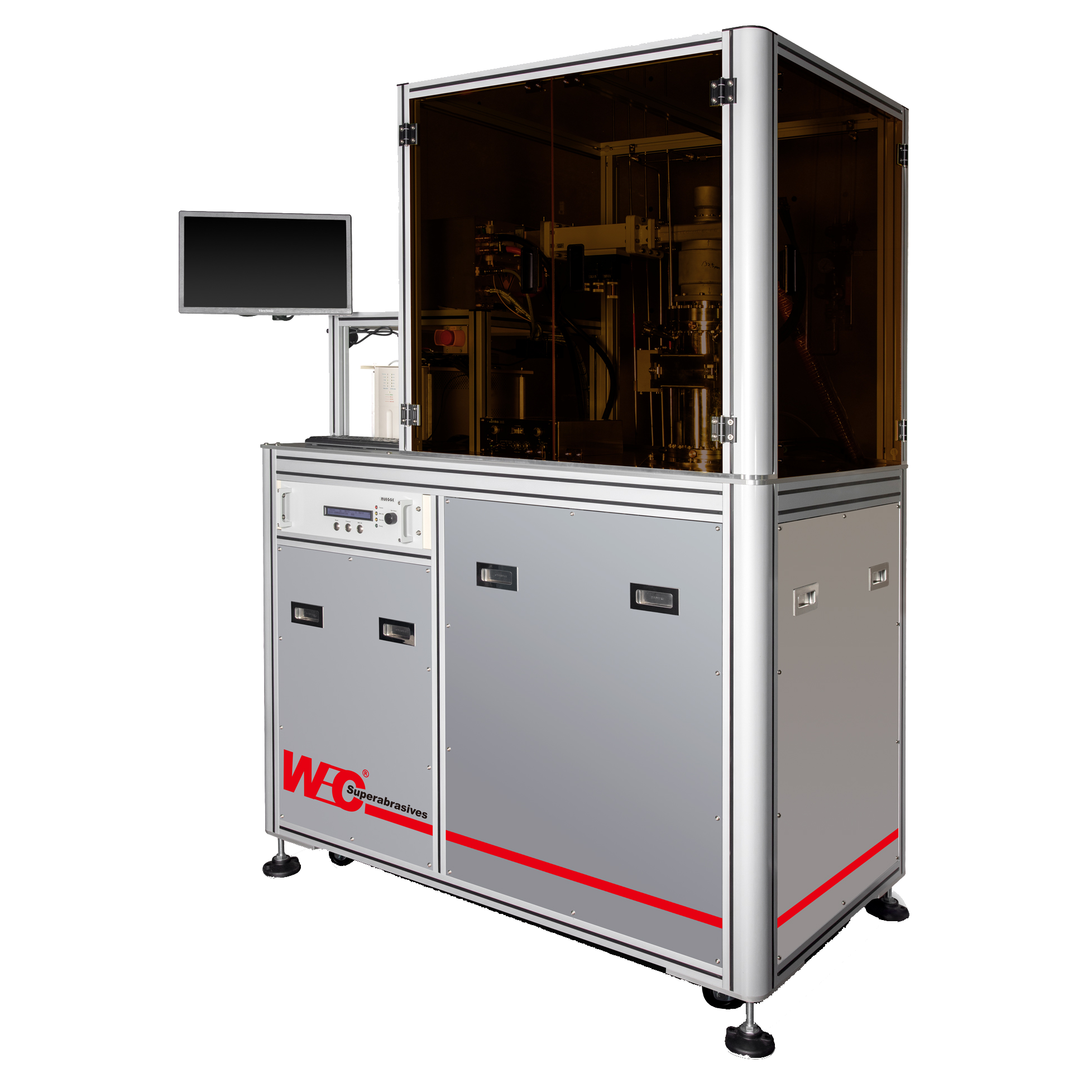

WEC-MP6000d is the most advanced CVD system capable of producing high-quality CVD diamonds for use in various industries

MPCVD (Microwave Plasma Chemical Vapor Deposition) Microwave Plasma Chemical Vapor Deposition method refers to high-purity hydrogen generating high-energy plasma fireballs under the action of powerful microwaves, and high-purity methane gas becomes free carbon atoms and hydrogen atoms under the action of plasma. Under the action of powerful energy plasma, these free carbon atoms will gradually deposit on the diamond seeds at the bottom in a three-dimensional arrangement, making the diamond seeds gradually grow thicker to form a CVD artificial diamond that is exactly the same as the "natural diamond structure & composition".

• Faster crystal growth speed - 10-100 times faster than traditional methods, beneficial for the industrialization of single crystal CVD.

• Increased production capacity - Higher output per batch, with larger crystal growth reaction chambers.

• Higher quality performance - Harder and more resilient than natural diamonds.

• More diverse colors - White, yellow, pink, blue, and more colored diamonds.

• Higher diamond purity - Purer than natural Type-II diamonds, suitable for applications in optoelectronics, semiconductors, and more.

• Customization for diverse styles - Customizable to meet different market demands (personal, cultural, religious, etc.).

• Gem, Lab-grown diamond

• Optical components

• Shaping & Dressing tools

• Cutting tools

• Heat spreader

• Electrochemical electrodes

• Power devices

• Electric components

• Electron emission device

• Sensors, MEMS, etc

–